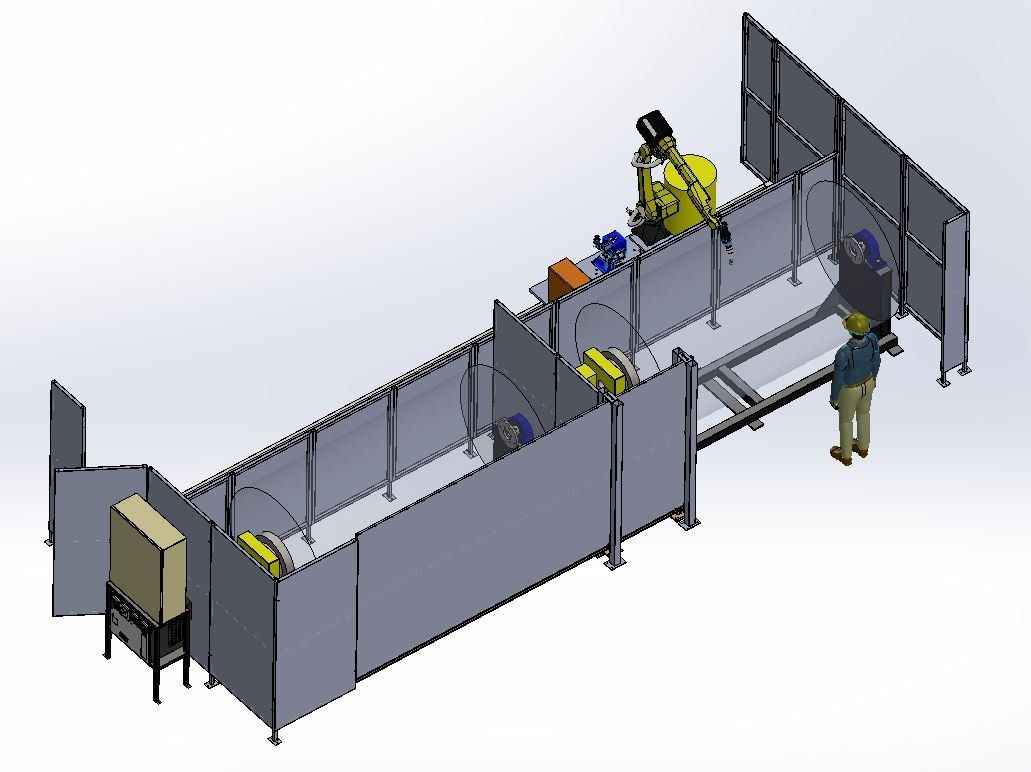

Cyber-Weld build a new welding cell for Unifabs Ltd

Twin manipulator System successfully installed by Cyber-Weld

Cyber-Weld has launched into 2020 with another successful installation of a robotic dual station cell into Unifabs Ltd, manufacturers of roadside hedge trimming equipment.

This standard cell comprises of a Fanuc ARC Mate 100iC 8L robot on an 8m long track, that serves two 3m long single-axis positioner stations. The advantage of such a cell layout is that the robot can serve either or both stations; enabling the tooling to be changed on one station whilst the robot is still welding on the other.

The full system was at the Cyber-Weld factory in Southam, the system was fully designed, manufactured, assembled, set up, commissioned, programmed and tested to the customers' satisfaction before being shipped and installed on the Unifabs Ltd site.

The system was designed to weld the mild steel components using a Kemppi A7 weld set, along with a Binzel torch, hose bundle and wire feeder. The system options included a Binzel torch cleaner and a TCP Laser check station, imperative options for a repeatable and reliable welding system.

Jason Austin, Managing Director of Unifabs Ltd said of the investment:

“Automation is manufacturing’s major opportunity and we’re excited to be able to offer robotic welding to our customers that require welded assemblies. We’re finding more and more customers are asking us to manage the whole manufacturing process for them, including welding, assembly and powder coating. To have the capability to produce more consistent, repeatable welds on the products we manufacture gives us the platform to offer an even better and more reliable service to our customers.”

Learn more about their subcontract manufacturing services at www.unifabs.eu.

Interested in a Robotic Welding Cell?

If you want to see more of this or are interested in robotic solutions for your manufacturing, please contact us.