Advanced Welding Techniques for Cobots

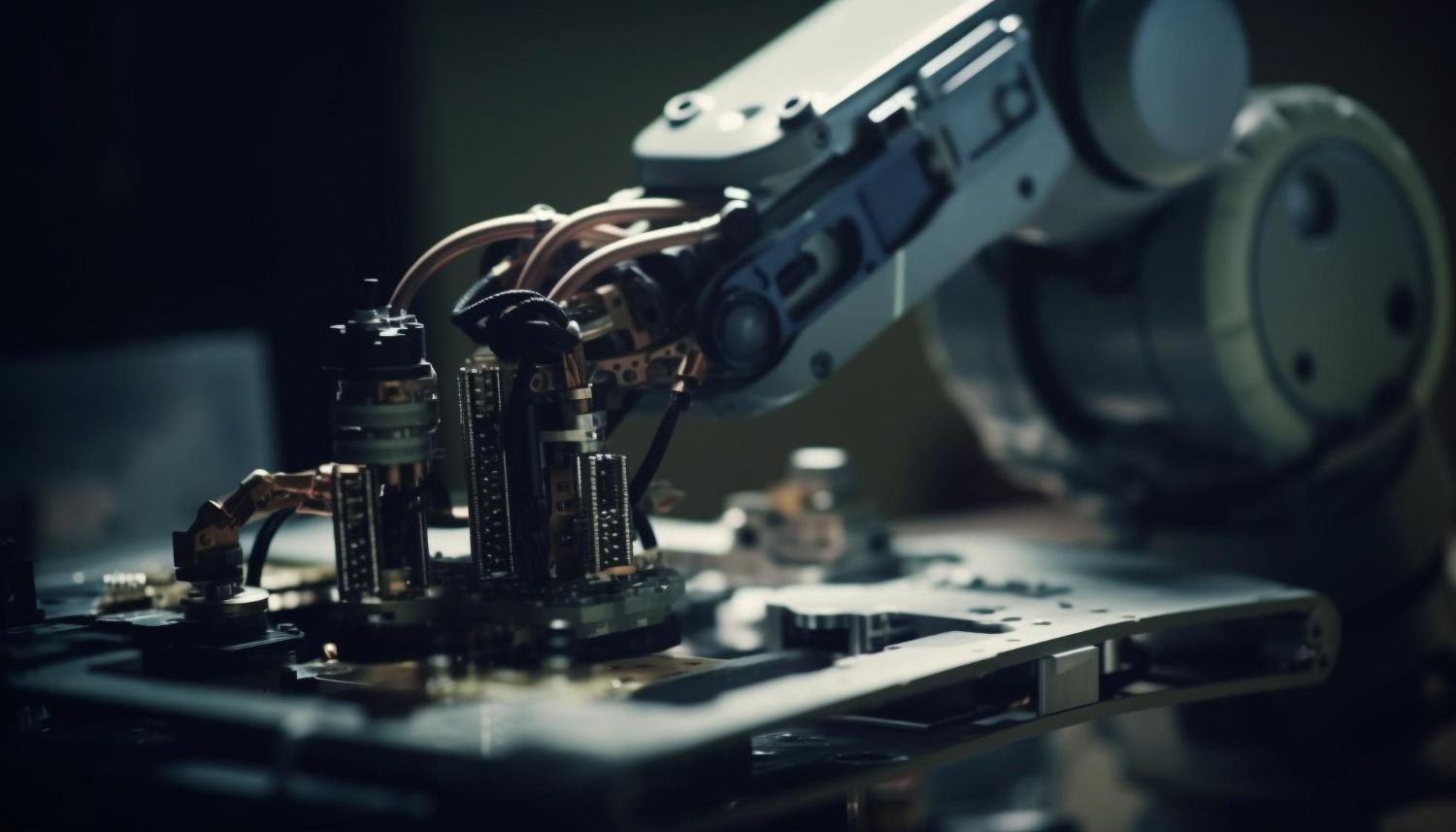

Collaborative robots or cobots have pushed the manufacturing industry on a transformative shift in recent years. Their integration into various production processes has allowed manufacturers to enhance efficiency, precision, and safety when working beside human operators.

Among the many applications of cobots, welding stands out as a domain where these intelligent machines have made remarkable strides.

This article will explore the types of advanced welding techniques cobots can use and how production lines can benefit from using them.

Benefits of Cobots in Advanced Welding Techniques

Why bother with advanced cobot welding?

Basic welding can be used for everyday tasks, repairs, and projects where functionality is the primary concern. For garden fences and broken metal chairs, basic welding will do just fine.

But when you’re fabricating parts for a spacecraft, creating delicate medical devices, or engineering high-performance automotive components, advanced welding techniques are non-negotiable. Some benefits of using cobots with advanced welding techniques are:

1. Precision and Consistency: Cobots, with their unyielding accuracy and tireless consistency, create welds with surgical precision. They don’t suffer from fatigue, ensuring every weld is as perfect as the last one, whether it’s the first hour or the hundredth.

2. Increased Efficiency: Cobots are extremely efficient. They work tirelessly, 24/7 if needed, reducing production time and increasing overall efficiency of your manufacturing line. No breaks or coffee runs, just uninterrupted welding prowess.

3. Enhanced Safety: Designed to work alongside humans with minimal risk of injury and accidents, cobots are extremely safe. They can handle hazardous materials, extreme heat, and tight spaces. They help keep human workers out of harm’s way making workplaces safer than ever.

4. Adaptability and Flexibility: Cobots are like chameleons. Easily adaptable, cobots can learn various welding techniques and work on almost any material and tasks required. Intricate TIG welding on delicate components? Train your cobots once and you’ll have an entire production line ready to go. Heavy-duty MIG welding on large structures? They’ve got it covered. Their flexibility ensures cobots can seamlessly switch between tasks without missing a beat.

5. Skill Shortage Solution: Skilled welders are more difficult to come by because of how long it takes for them to learn and master a skill. So what can you do when there is a shortage of skill? Cobots. They don’t need years of training and experience; all they need is programming. This addresses the skilled labour shortage in the welding industry. A single skilled welder can help train and program your entire cobot line.

6. Cost-Effectiveness: While cobots might seem like a hefty investment upfront, their long-term benefits far outweigh the costs. With increased productivity, reduced errors, and minimal downtime, they provide excellent returns on investment, making them a financially sound choice for manufacturers.

Types of Advanced Welding

Cobot Laser Welding

Laser welding has long been recognised for its accuracy and speed. When combined with cobot technology, it becomes a powerhouse for precise welding tasks. Cobot laser welding systems utilise high-powered lasers to melt and fuse metals with minimal heat-affected zones. Cobots equipped with laser welding capabilities excel in intricate welding tasks, such as thin materials or complex geometries. The real-time monitoring and adjustments by cobots ensure consistent quality, making them invaluable in industries where precision is paramount, like aerospace and medical device manufacturing.

Cobot TIG Welding

Tungsten Inert Gas (TIG) welding or cobot TIG welding is renowned for producing high-quality welds. Cobots equipped with TIG welding capabilities offer several advantages, such as giving manufacturers unmatched control over the welding process, making them ideal for applications involving exotic materials or critical joints.

The steady hand of a cobot ensures a stable arc, preventing defects like porosity and ensuring a flawless finish.

Cobot MIG Welding

Cobot MIG (Metal Inert Gas) welding involves the use of a continuously fed wire electrode to join metal pieces. The process uses a shielding gas (typically a mixture of argon and carbon dioxide) to protect the weld pool from atmospheric contamination, ensuring clean and robust welds.

It finds applications in various industries, including automotive manufacturing, aerospace, shipbuilding, and fabrication. This technique is used for welding components such as chassis, frames, brackets, and other structural elements where strength and precision are critical.

Cobots bring a significant impact in the manufacturing landscape. They help bridge the gap between the skilled labour shortage and knowledge of advanced welding techniques. As cobots continue to evolve, their impact on the welding industry is bound to grow.

Manufacturers embracing these innovative solutions are poised to experience higher efficiency, improved product quality, and enhanced workplace safety. With cobots leading the way, the future of welding is not just precise and efficient but also collaborative and intelligent, revolutionising how we perceive and accomplish complex welding tasks in modern manufacturing.

Ready to elevate your welding operations and outshine your competitors? Cyber-Weld’s expert team can provide you with a tailor-made welding cobot package designed to transform your business.

Unlock the potential of your business with our advanced welding cobot solutions!

Reach out to us to continue the conversation and discover how our innovative solutions can revolutionise your welding processes and efficiency. Don’t miss out on the future of welding technology — contact us today.