Exploring Collaborative Robotic Grippers

Industrial robots are essential tools across various sectors in the manufacturing industry. From automation to healthcare, every industry uses robots. However, with the advent of collaborative robots, or cobots, a new era of human-robot collaboration has emerged. Unlike traditional industrial robots confined within safety cages, cobots are designed to work alongside humans, fostering a seamless and efficient partnership on the manufacturing floor.

The key to cobots' versatility lies in the cobot gripper technology which gives them the ability to move from welding to a wide range of tasks, such as assembly and packaging. Collaborative robot grippers serve as their interface with the physical world, enabling precise manipulation, lifting, and placement of objects.

We’ll dive into cobot grippers to understand what they are, what types are there, and how they allow cobots to move beyond simply lifting and welding.

Definition and Role of Collaborative Robotic Grippers

The collaborative robot gripper is an advanced end-effector specifically engineered for use with cobots. Cobot grippers act as the interface between the cobot and the objects it handles, enabling precise manipulation, lifting, and placement tasks.

These grippers are equipped with advanced sensors and sophisticated control systems, allowing them to adapt to a vast array of object characteristics, including intricate shapes, varying sizes, and diverse materials. The primary purpose of gripper adaptability is to allow cobots to handle a wide range of tasks with unparalleled flexibility and precision.

Types of Collaborative Robotic Grippers

Collaborative robotic grippers come in various forms, each designed for specific applications and environments. Some common types include:

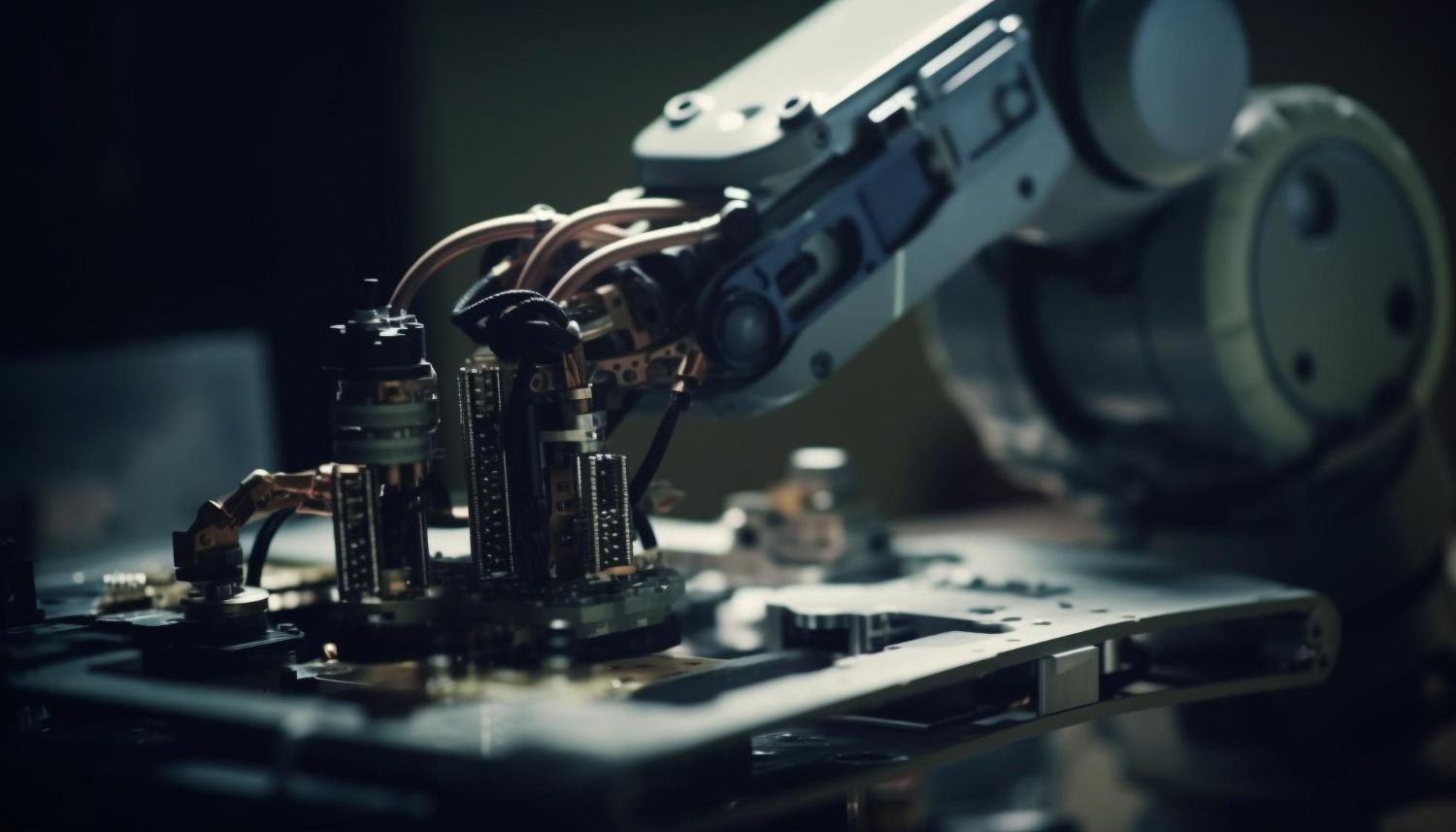

Parallel Grippers

Parallel grippers feature two opposing jaws that move simultaneously to grasp objects securely. These grippers are versatile and suitable for handling a wide range of objects with different shapes and sizes. For example, these grippers for collaborative robots are commonly used in pick-and-place operations, such as assembling electronic components on printed circuit boards or moving machined parts from one station to another. They are also widely used in packaging processes, such as gripping and placing products into boxes or containers.

Vacuum Grippers

As the name sounds, vacuum grippers utilise suction cups to grip objects securely. They are particularly effective for handling flat or smooth-surfaced objects, such as glass panes in the automotive industry, metal sheets in fabrication processes, or electronic components like computer chips and circuit boards. Vacuum grippers are widely employed in industries such as electronics manufacturing, where they are used to transfer delicate components during assembly, as well as in logistics and warehousing for handling packages and containers.

Soft Grippers

Soft grippers, often made from flexible materials such as silicone or rubber, offer gentle and careful handling of delicate objects. These cobot grippers are ideal for tasks that require careful manipulation, such as handling fresh produce in food packaging processes, assembling fragile medical devices in the pharmaceutical industry, or handling delicate glassware or ceramics in consumer goods manufacturing.

Adaptive Grippers

Adaptive grippers employ advanced mechanisms such as compliant fingers or articulated joints to adapt to the shape of objects. They excel in handling irregularly shaped or fragile items that traditional grippers may struggle with. For example, adaptive grippers are valuable in the consumer goods industry for picking and packing oddly shaped items, in e-commerce fulfilment centres for handling a wide variety of products, and in medical device manufacturing for handling intricate and delicate components.

Applications of Collaborative Robotic Grippers

These specialised grippers, each designed with unique capabilities, have unlocked new frontiers across industries. They have become indispensable tools that enable precise and efficient task execution while ensuring safe collaboration with human workers.

Manufacturing

In manufacturing facilities, cobot gripper technology is revolutionising manufacturing processes. Equipped with cobot grippers these robots can seamlessly handle tasks like assembly, material handling, and quality inspection alongside human workers. The advanced grippers enhance efficiency and flexibility on the factory floor while ensuring a safe working environment for employees.

Logistics and Warehousing

Cobots with grippers are in logistics and warehousing operations to help with optimising order fulfilment, palletising, and inventory management. Their ability to handle packages and products swiftly and accurately reduces errors and increases throughput in distribution centres.

Healthcare

In the healthcare industry, lives depend on precision and safety. Cobots equipped with specialised grippers assist in crucial tasks like medication dispensing, specimen handling, and surgical instrument management. These collaborative robots contribute to improving efficiency and accuracy in healthcare delivery, minimising the risk of human error.

Agriculture

Even agricultural operations benefit from cobot grippers, which can automate labour-intensive tasks such as harvesting, sorting, and packaging crops. These robotic assistants enhance productivity while reducing labour costs, contributing to sustainable farming practices. With their adaptability and precision, they can handle delicate produce with care, ensuring quality and minimising waste.

The integration of cobots has revolutionised the way we approach automation across various industries. From manufacturing and logistics to healthcare and agriculture, these advanced grippers have unlocked new levels of efficiency, precision, and safety. With advancements in cobot gripper technology, cobots will soon be able to perform more intricate and delicate tasks currently reserved only for human operators.

If you're exploring ways to optimise your business operations and stay at the forefront, integrating cobots with advanced gripper technology is the way. Looking to revolutionise your manufacturing processes with cobots? Contact our UK team now.

Recent Posts

Knowledge Hub

Since 1998 we have been supplying new and reconditioned welding robot systems to companies all across the world. We have large client base and a very experienced team specializing in all aspects of robot welding and systems.

CYBER-WELD LIMITED

• Registered Company No: 02492536

• VAT Registration No. GB 337784756

• VAT Registration No. GB 337784756