The 7 Types of Robotic Welding Processes

Ben Ellis • March 18, 2019

The following are some of the most common forms of robotic welding:

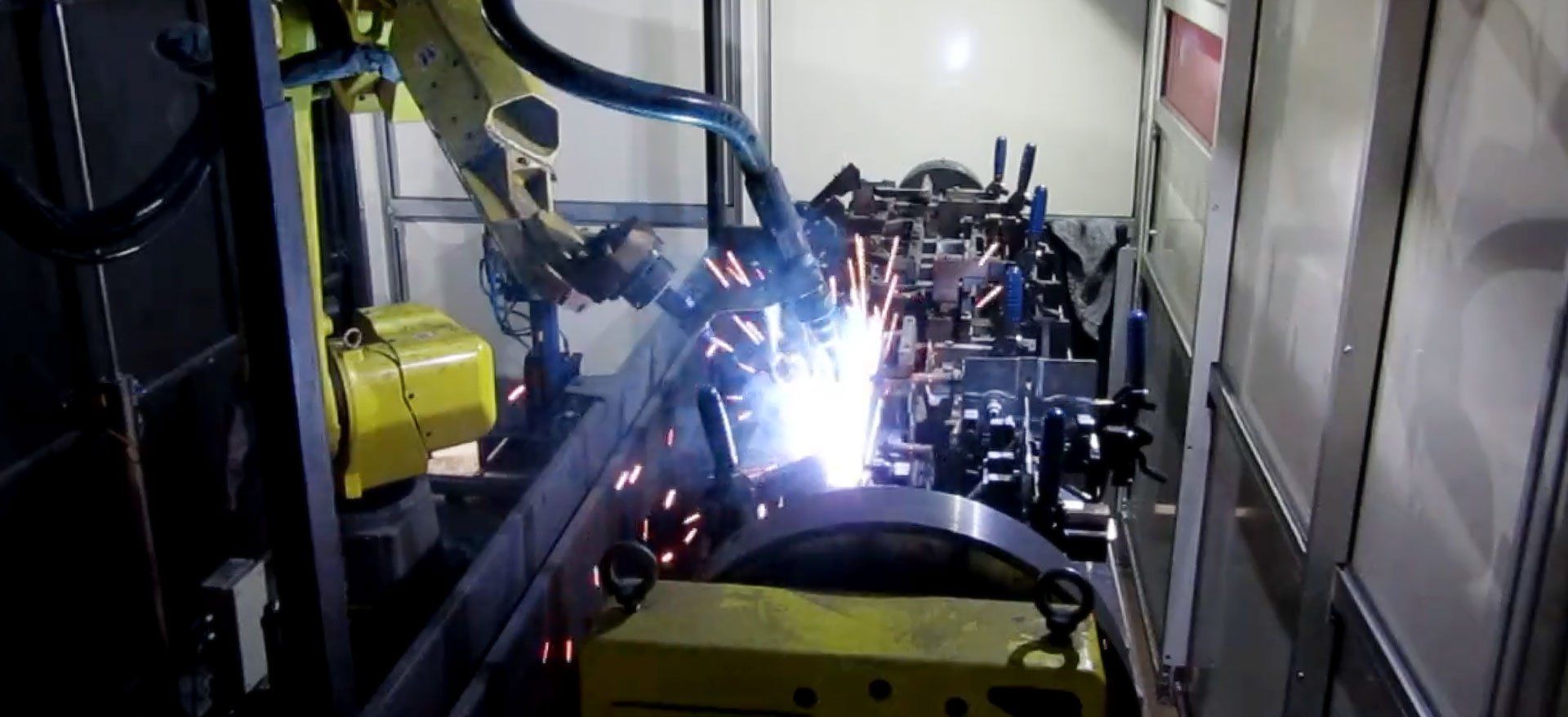

1. Arc Welding:

an electric arc between an electrode and metal base produces an intense heat to melt and intermix two parts. Arc welding is used for applications calling for high accuracy and repeat-ability.

2. Resistance Welding:

a current is passed between two metal pieces of metal, a pool is formed by the resulting heat, and the two pieces are joined together. Resistance welding is the most economical form of robotic welding and is best for heat-treating projects.

3. Spot Welding: a type of resistance welding, spot welding joins thin metals that resist electrical currents. It’s typically used in the automotive industry to join sheet metal frames together.

4. TIG Welding: a high-quality process where an arc is formed between a non-consumable tungsten electrode and the metal part. Also known as Gas Tungsten Arc Welding (GTAW), TIG welding is used when precision is of the utmost importance.

5. MAG Welding: a high deposition rate process that involves feeding a wire continuously toward the heated weld tip. Also known as Gas Metal Arc Welding (GMAW), it is best for applications where system simplicity and speed are desirable.

6. Laser Welding: a laser generator delivers via a fiber optic cable a laser light through a robotic cutting head to weld pieces together. Laser welding, including remote laser welding for hard to reach weld locations, is often used in high volume applications that require high accuracy, such as the automotive sector or in the medical or jewelry industries.

7. Plasma Welding: ionized gas passes through a copper nozzle to produce extremely high temperatures. Plasma welding is used when flexibility is required, as velocity and temperatures can be easily adjusted.