Robot Operating Systems: An Overview

If you need a practical framework on which to develop robotic systems, a robot operating system can provide the groundwork you need for your project.

Robot operating systems are essentially a type of robotic middleware, a pre-developed package of tools that can be employed as a base on which to build software that’s specific to your robot. A robot operating system removes the need to develop independent software for each robotics project; you simply tailor the existing framework to suit your robotic needs.

Robot operating systems have become an essential feature of the robotics industry, saving developers time while allowing them to become more flexible in their work. In this article, we explain what a robot operating system is, what they are used for, and the different types of robot operating systems available.

What Is a Robot Operating System?

Any robotic system is necessarily composed of a number of different hardware elements – be it motors, robotic arms, monitors, etc. – which only work together when they are effectively connected and able to communicate with each other. To connect these components together, you need a robot operating system.

Imagine having to build, develop and design all of these components and the software to connect and control them, from scratch. That would be an incredibly time-consuming project that requires an intense level of skill and years of expertise.

Indeed, because robots are so complex, the extent and depth of knowledge required to create a fully-functioning robotic system from scratch would prove almost impossible for most people to achieve, at least not without extensive training, knowledge and skills.

Just thinking of the number of different components that would be needed is enough to put most people off the task. But that’s where a pre-developed robot operating system comes into play, providing access to a pre-developed package that allows you to seamlessly connect all these components.

A robot operating system is an effective framework that allows you to develop the necessary robotic software so these hardware elements can communicate and the robotic system can complete the task it was designed for.

It’s a type of framework that allows you to build and operate a robot without having detailed knowledge or data on every individual part or component, as much of this knowledge or data already exists in the base software.

A robot operating system is generally composed of two primary components:

- A software framework

- A developed library of applications, tools and plug-ins

A robot operating system allows you to connect and communicate different elements of robotic hardware using this database of pre-developed software, creating an effective way to model the robot, create it and operate it. Think of the robot operating system as the base layer of software around which you connect and interconnect the hardware for the robot and which allows you to operate your robot.

The most well-known type of robot operating system is simply called Robot Operating System (ROS). This particular system provides the framework upon which a vast number of other robotic operating systems are developed.

Operating System or Middleware?

The term ‘operating system’ is actually slightly misleading, as a robot operating system is generally considered to be a form of robotic middleware. The goal of this middleware is to provide you with the necessary software you need to design a system that means you can control the robot you’re creating.

Perhaps surprisingly, this means the type of framework we are discussing is not technically an ‘operating system’. A robot operating system needs to go on top of an existing operating system in order to work; they commonly run off the back of popular programmes such as Linux or Windows. The programming language used is commonly Python or C++, ensuring that a robot operating system can effectively communicate across multiple applications.

Interestingly, a robot operating system is often based on open-source software. This means they are highly compatible with existing software and hardware, and they are continually being developed and updated. It also means there’s already an extensive library of data and tools available to use.

A robot operating system contains a large number of existing tools, alongside an extensive collection of ‘libraries’ that contain pre-developed applications to help streamline the development process. For example, if you are modelling different parts for your next robot system, you can often choose to use existing data from a library to decide which parts are best suited for the project.

A robot operating system such as ROS contains all the necessary tools you need to develop, design, test and operate a fully functioning robotic system. Once the basics have been learned, it’s an effective framework that can help you to create complex robotic systems in a short space of time, which would otherwise take years to develop.

What Are Robot Operating Systems Used For?

Robot operating systems are required for almost any complex robotic system. They exist as a way to control and operate robots, and anything from an automated welding system to a pick-and-pack robot will be run off the back of a robotic operating system.

Within this broad remit, a robot operating system can help with a number of different applications to reach the ultimate goal of controlling the robot, including:

- Connecting robotic hardware elements

- Providing communication between robotic hardware

- Creating 3D robotic simulation models

- Developing path planning, localisation and mapping

On a more practical level, these applications allow you to programme a robot to perform a vast number of functions. For example, robot operating software allows you to connect a joystick to a robot, or to ensure that a robot can use cameras to become spatially aware of its surrounding environment.

A single robot might have multiple tools and applications built into its design, and all of these individual elements can communicate with each other and the central control system to create a coordinated system. Simply put, without a robot operating system, your robot wouldn’t be able to move or perform the tasks it’s intended to perform.

Robotic systems are required for a wide number of purposes, but they are particularly suited to automated tasks. Examples of robot operating systems in action include:

- Robot welding systems

- Assembly robots in factories

- Pick-and-pack robots in warehouses

- Quality inspection robots

For almost any given task that can be automated, robot operating systems can provide the required groundwork for you to design, create and operate a suitable robotic system. In many cases, the software and applications you would require are likely to be found in an operating system library. If not, the code and basic elements of the software will likely exist and can be expanded upon.

Types of Robot Operating Systems

There are several different types of robotic middleware software available and, as explained, much of it is open-sourced and continually being developed and improved.

The most common system is the aptly named Robot Operating System (ROS), which provides the basic tools, applications and coding for a large percentage of the world’s robots. In many cases, ROS forms the basis for many more robot operating systems, which use the readily available resources to develop specific types of robot operating systems to meet different needs.

Let’s take a closer look at ROS and FANUC ROBOGUIDE, two types of popular robot operating systems.

Robot Operating System (ROS)

ROS is the primary robotic operating system available to developers. It’s open-sourced and sits on top of existing computer operating systems.

ROS is the backbone of the robotics world. Its main goal is to ensure that developers don’t have to continually create new applications and tools for different projects, but can draw upon a vast and ever-expanding collection of code that is likely to suit most needs.

Other commercial operating systems will likely incorporate many elements of ROS into their own design, making this an indispensable operating tool.

FANUC ROBOGUIDE

FANUC ROBOGUIDE is a robot simulator that’s been developed by FANUC, a major manufacturer of industrial robots.

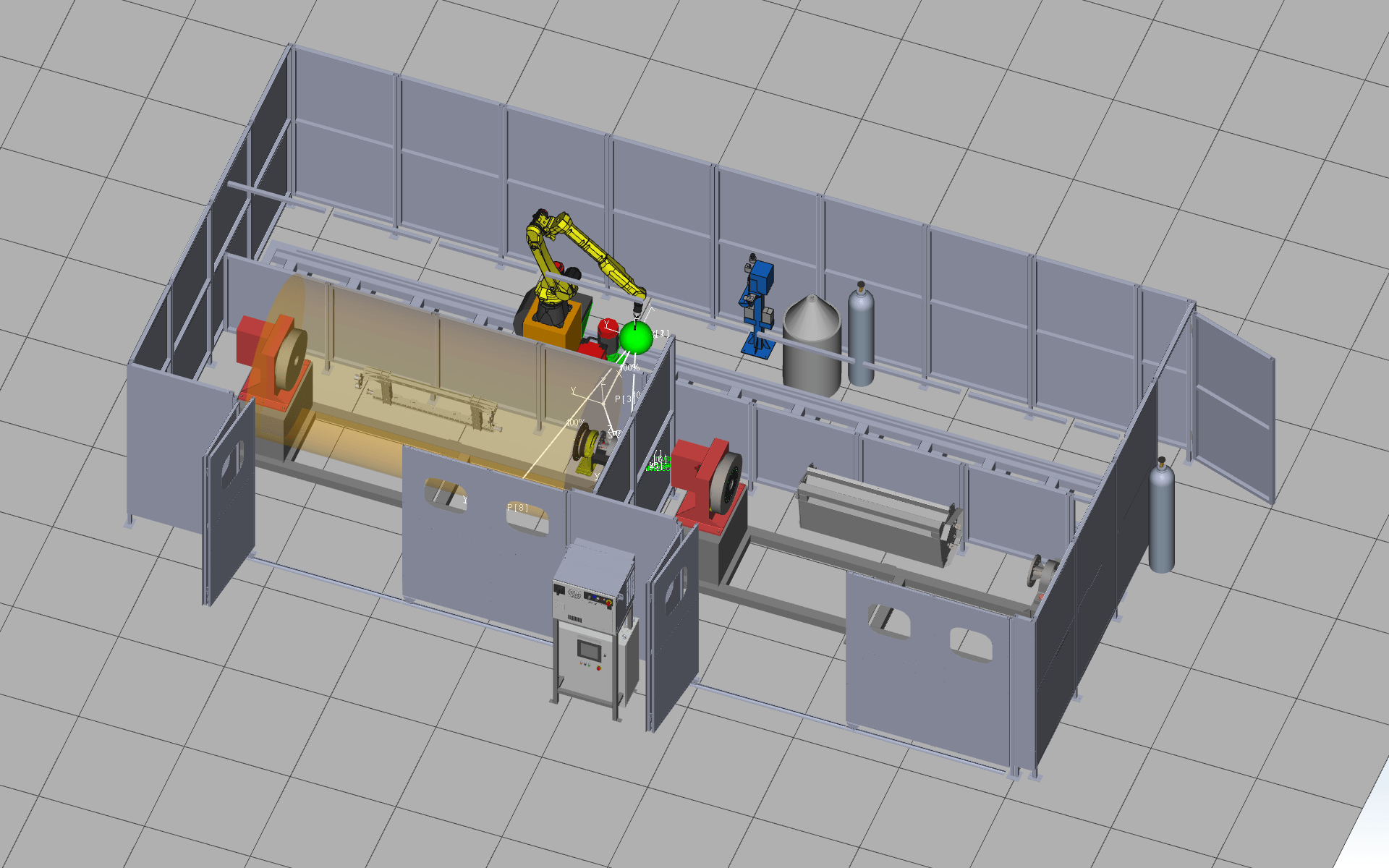

FANUC ROBOGUIDE is a purpose-built operating system designed to simulate a robot’s potential actions in order to allow system designers to create accurate 3D models.

As an operating system, FANUC ROBOGUIDE allows existing data to be imported from an extensive library of parts, allowing different robotic parts to be quickly trialled using CAD. The system is easy to use, incredibly flexible and intended to save time and resources by allowing 3D modelling to be carried out offline.

Components of Robotic Systems

A robotic system as a whole will have a number of individual components that allow the system to coordinate, communicate and accomplish its intended tasks. This could include components such as a robot arm, controller, and the software needed to run the robot.

The robot operating system is one major component of any robot. Within a robot operating system, there are also a number of different components that make up the system. With ROS for example, there are five major components. These are:

- ROS Master: provides overall control and communication between different components within the operating system.

- Nodes: individual nodes within a system usually provide a specific function, such as movement or sensors, and relay data back and forth to the ROS Master.

- Topics: topics allow information to be communicated between different nodes in the system.

- Publisher: the name was given to the message sent out by a node.

- Subscriber: the name given to a message received by a node.

As you can see, the main purpose of these individual components is to allow communication within the system. A robotic operating system, like ROS, allows the different components within the wider robotic system to function.

On a broader spectrum, any robotic system requires several major components to be effective. These include:

- Robot operating system: The software, middleware or framework upon which the system is built and can be operated.

- The Robot: The robot or robot parts, which can be supplied in whole by companies such as FANUC and often run on a pre-installed robot operating system. The type of robot will depend on the function of the system. For example, welding tasks can be automated by purpose-built welding robots.

- Controllers: You need a way to control the robot and its movements, and a way to communicate with the robot operating system. A controller could be a computer programme that’s accessed through a monitor, touchscreen or joystick, for example. The control process could also be automated.

- Functional attachments: To complete tasks effectively, robots are often equipped with functional attachments, such as a welding arc.

Examples of Robotic Operating Systems

A fully operational robotic system is made up of a complex and interconnected array of components that provide it with the hardware and software to complete the tasks it was designed for. The robot operating system enables all of these components to communicate and be controlled.

Popular examples of robotic operating systems include robotic welding machines that can use TIG or MIG components to perform welding tasks. Another common example would be car assembly robots, which can be kitted out with different attachments that allow them to assemble parts, weld materials together, or spray paint vehicles. The list goes on; with a flexible robot operating system to draw upon, almost any type of robotic system can be designed.

Contact Cyber-Weld Today to Find Out More About Robot Operating Systems

If you’re looking to automate your production, manufacturing or design processes with the help of robot operating systems, the expert team at Cyber-Weld are here to help. Our experienced engineers are specialists in designing and building robotic systems that can be implemented across an impressive range of industries.

We can provide full-service robot system packages, and tailormade to meet your industrial needs. Our friendly staff will be there at every stage of the process, from the initial concept and planning stage, right through to after-sales and continued robot servicing and support. To find out more about our bespoke services, contact the Cyber Weld team today.