Cyber-Weld's Top 5 Advantages of Robotic Welding

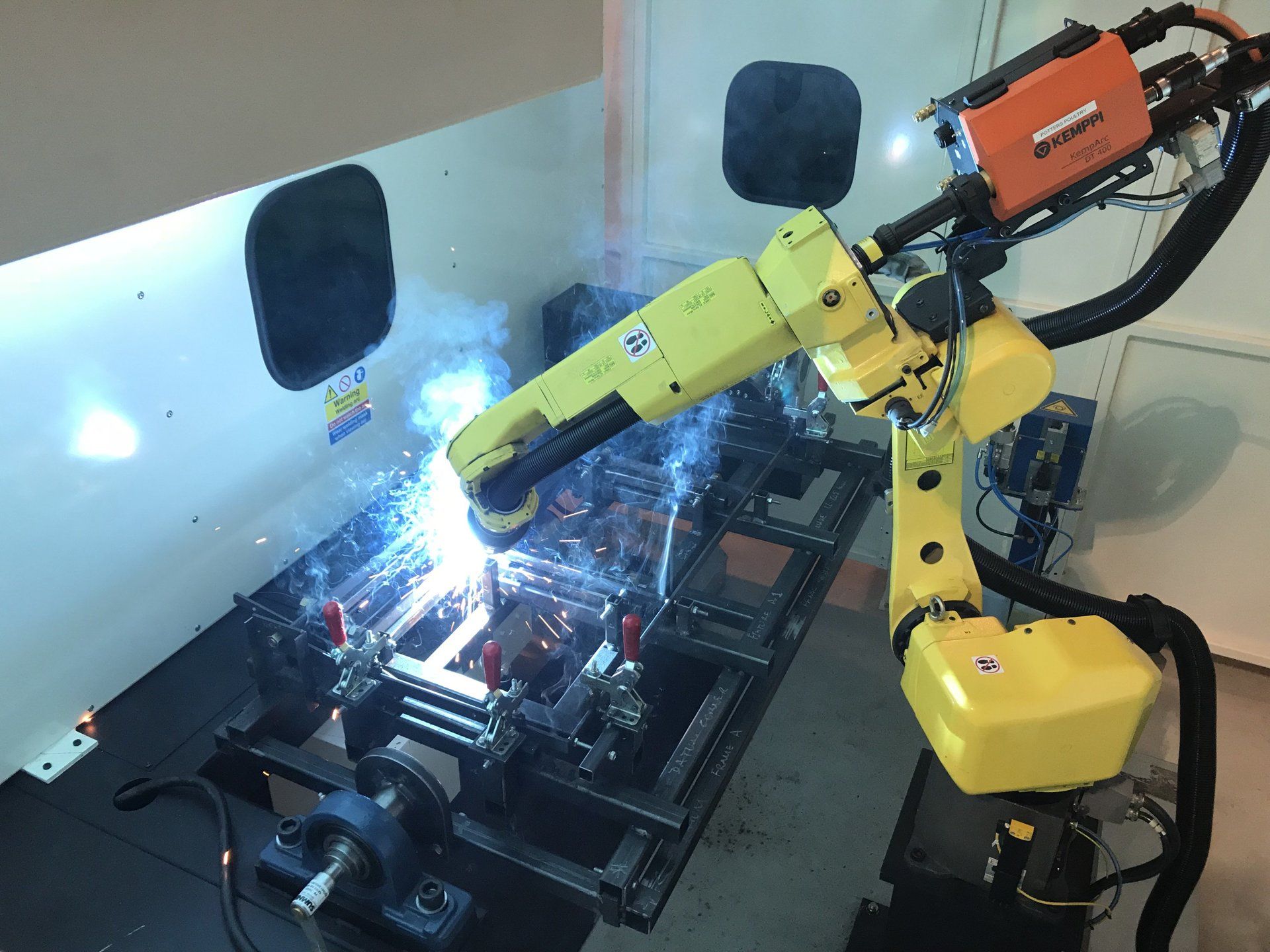

One of our latest systems to be completed and Installed at our Sertec. It is a spot welding system with tooling.

Increased Quality

Robotic welding systems help you speed up your output. They also perform tasks with high accuracy, eliminating the need to repeat tasks, which wastes time. Unlike manual welding, which relies on human labourers, robotic systems do not stop for breaks or sick days. Once you master the settings and programming needed for each weld, you can run the systems around the clock, allowing you to increase your productivity and meet client deadlines with ease. Robotic systems also perform precisely with minimal splattering reducing the time spent cleaning up after a job. Cycle times are shorter: The manufacturing line becomes more efficient, making cycle times much shorter. More can be produced in this time as opposed to what is available when working with human employees.

Cost Effectiveness

Robotic systems improve efficiency, which saves you time, resources, and reduces operational costs. Through robotics, you increase consistency, productivity and deliver better quality. Other costs saving opportunities include reduced compensation for workers and energy saving costs. Cost saving cuts the cost of production, subsequently reducing the overall cost of the product, giving you a competitive advantage when sending quotations to clients.

Safety

Workplace safety is increased and improved: Workers will no longer have to perform dangerous welding jobs, and can be moved into supervisory roles. Hazardous positions will fall away because the robots will perform the welding jobs that can cause injury and accidents.

Increased Efficiency

Industrial robots are able to complete certain tasks faster and better than people, as they are designed to perform these tasks with a higher accuracy level. This and the fact that they are used to automate processes which previously might have taken significantly more time and resources, means that you can often use industrial robots to increase the efficiency of your production line.