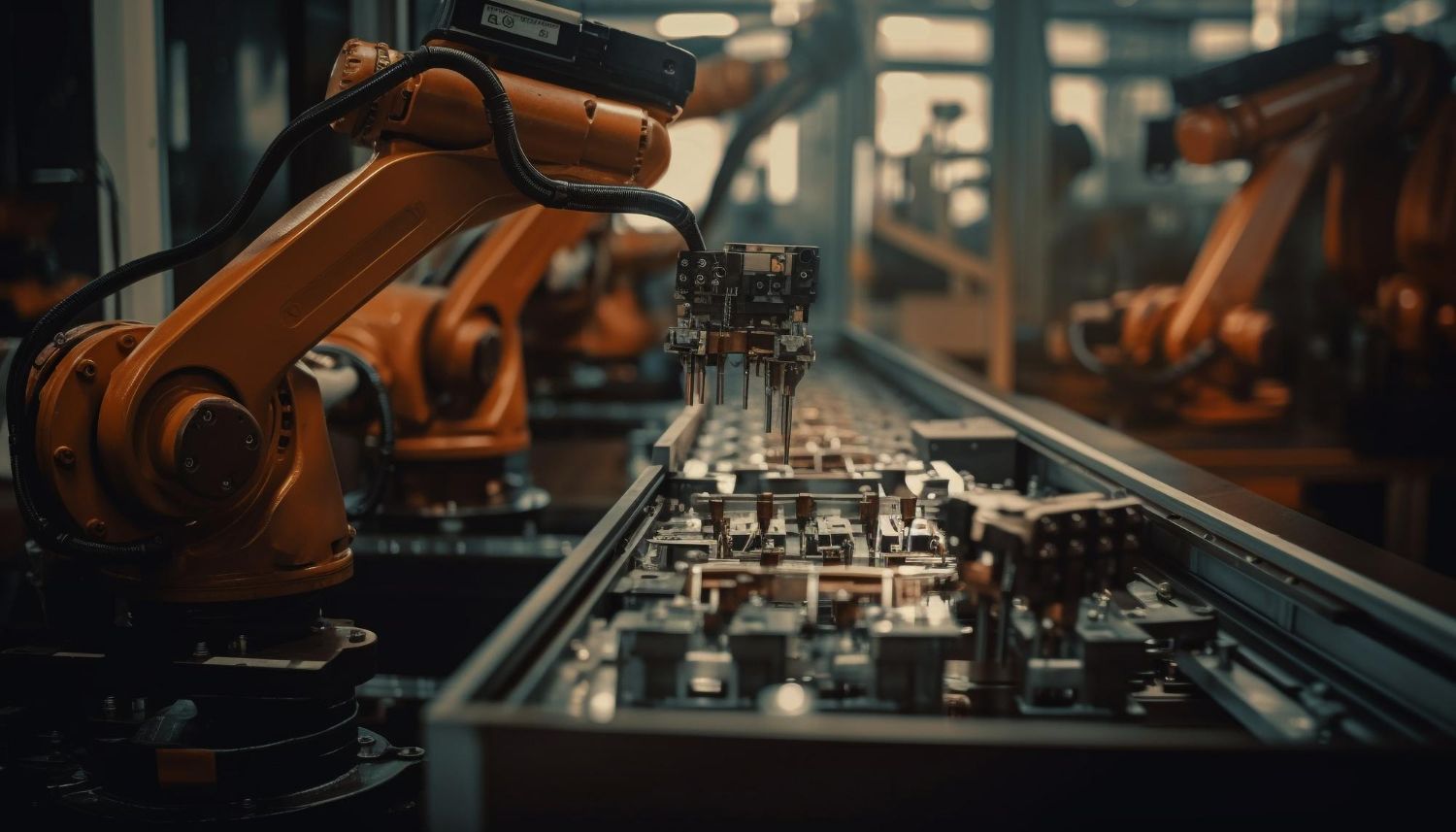

Cobot Welding in Automotive Manufacturing

With the inclusion of cobots in automotive manufacturing, the automotive industry shows signs of undergoing significant transformation.

Increased efficiency, quality control and enhanced worker safety are just a few things the industry is experiencing. Today we’ll dive into how cobot welding is a game changer for the automotive industry.

Increasing Efficiency in Automotive Manufacturing with Cobot Welding

Cobot welding technology streamlines automotive manufacturing processes and significantly improves efficiency of manufacturing by performing assigned tasks with high accuracy and low downtime.

These robots can perform repetitive and labour-intensive tasks with consistent precision, reducing the reliance on manual labour for welding processes. Unlike traditional welding robots that require extensive reprogramming and recalibration when there’s a change in product design or specifications, cobots are easily reprogrammed to accommodate new welding patterns or product variations. These features eliminate bottlenecks and ensure that each step of the production process operates at its optimal pace, reducing downtime and accelerating time-to-market for new vehicle models.

Successful Implementation of Cobot Welding in Automotive Manufacturing

While there can be significant challenges of implementation, numerous manufacturers have demonstrated that, with careful planning, cobots in car manufacturing can have significant benefits.

A key factor in successful implementation of cobot welding in automotive manufacturing is thorough strategic planning. Assess your current production processes, identify bottlenecks, and determine areas where cobots can provide the strongest impact. Being adaptable, cobots can be customised and programmed to match the specific needs of the production line, which can be done by configuring parameters, trajectories, and safety protocols to match your needs.

Collaborative Robots for Quality Control

Collaborative robots in automotive manufacturing goes beyond just increasing production efficiency; it plays a crucial role in ensuring that the final products meet the highest standards of quality and reliability.

One of the advantages of cobot welding is its ability to consistently create precise welding patterns on any vehicle. Cobot welding systems are also equipped with advanced sensors and cameras that enable real-time monitoring and inspection of the welding process. Variations that occur in welding parameters, such as temperature, voltage, and speed, can be picked up immediately by operators with the help of cobots. This proactive approach to monitoring helps identify potential issues before they escalate, reducing the likelihood of defective welds and minimising rework.

Enhancing Worker Safety in Automotive Manufacturing

Engaging industrial robots introduces safety considerations for human workers, but the integration of collaborative robot welding in automotive manufacturing makes human-robot collaboration easier and safer.

Traditional welding tasks involve exposure to hazardous conditions, but cobots mitigate these risks by removing human workers from direct exposure to these hazardous environments. In addition, welding tasks often require workers to assume fixed positions for long periods, leading to ergonomic strain and potential long-term health issues. Cobots alleviate this by taking over repetitive and physically demanding welding tasks, allowing human workers to focus on higher cognitive functions and reduce the likelihood of musculoskeletal injuries.

Future of Cobot Welding in the Automotive Industry

As manufacturers continue to embrace this innovative technology, the automotive landscape is set to undergo transformative changes that will impact efficiency, quality, safety, and overall competitiveness.

Future cobots are expected to possess advanced AI capabilities, enabling them to adapt to changing welding tasks and environmental conditions in real time. The AI algorithms can also analyse the data generated by cobots during welding operations to identify trends, predict failures, and recommend preventive measures. Resulting in a manufacturing process that seamlessly shifts to evolving product designs and customer preferences.

Cobot welders in the automotive manufacturing industry are changing the landscape by producing tangible benefits in efficiency, quality control, worker safety, and adaptability. With more businesses embracing this innovative technology, businesses can look forward to improved productivity, reduced operational costs, and an overall enhanced manufacturing process. The integration of cobot welding isn’t just a step forward; it’s a leap into a human-cobot collaborative future that drives progress and innovation.

Step confidently into the world of collaborative robots and experience their remarkable capabilities. Contact us today to find out how we can help you integrate cobot welding and other innovative cobot solutions for your business.