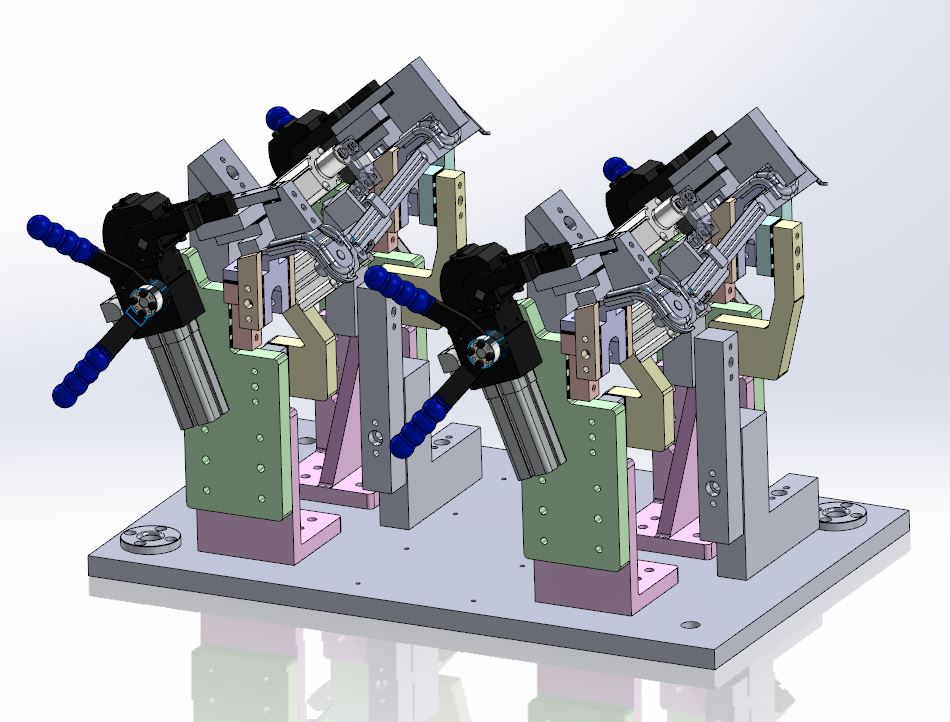

3D Design

Using the 3D CAD software package SolidWorks we are able to produce accurate designs of robotic systems and anything that these may require. This allows us visually represent every aspect of a system, whether it be from full tooling to mechanical tables to even minor bracketry in the guarding. Using the 3D models we create on SolidWorks we are able to ensure that the job is going to be able to work successfully before anything is even made. The models made on SolidWorks can then be converted to .IGES files and imported into to our robotic specific simulation software’s so that a simulation of the complete job can be created with the robot arm

to ensure the job can be completed successfully.

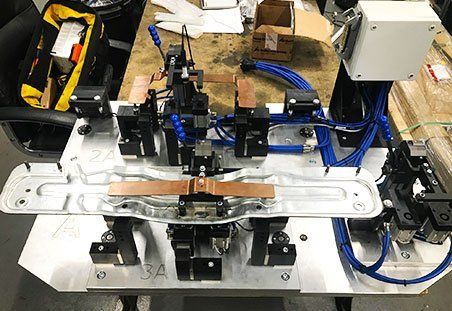

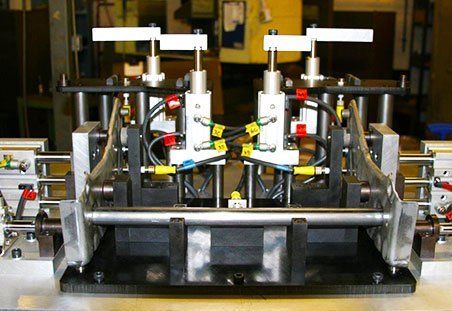

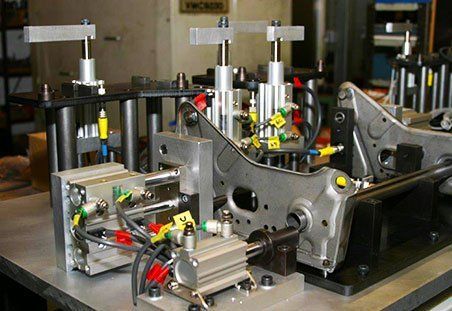

CNC Milling

At Cyber-Weld we can use our in-house machining centre to machine our own parts allowing us to build and test various parts including whole jigs and fixtures. With these new machining capabilities we are able to provide highly accurate parts for our customers allowing us greater ease in achieving smaller tolerances that may need to be hit. This machine allows us to accurately machine faces and drill and tap holes on various materials.

CMM

To check our parts are made correctly and to tolerance we use our Hexagon Infinite 2.0 portable CMM arm which is installed on a machined bed. This allows us to measure any part highly accurately (Within 0.020mm) against the CAD files or drawings to ensure it has been made within tolerance and is going to function correctly, this is especially important when we are creating jigs and fixture that need to be repeatable.

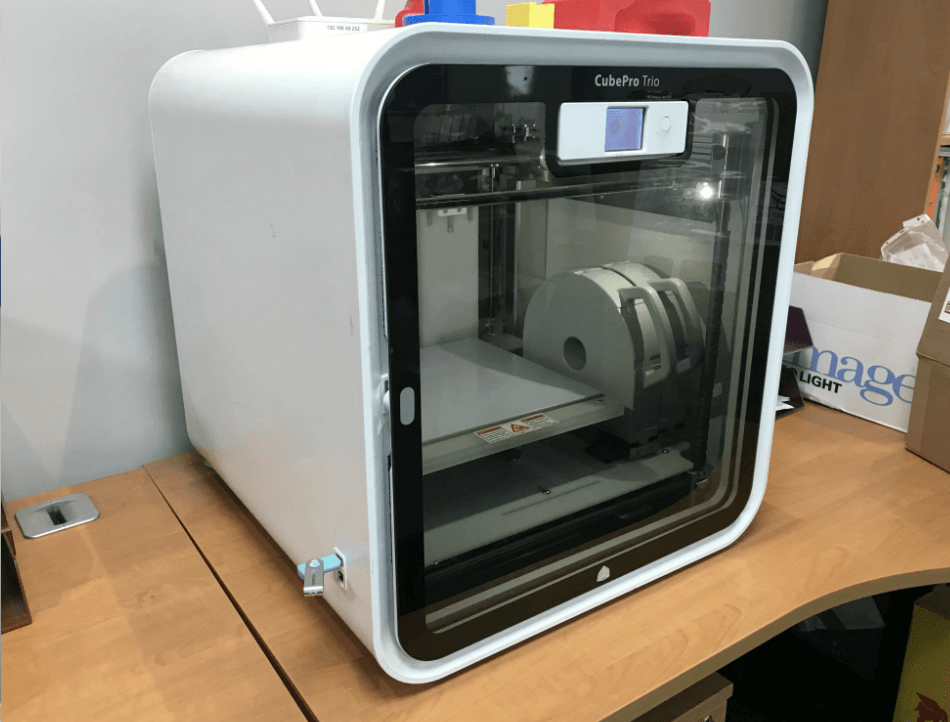

3D Printing/Scanning

We have the ability to further reduce the time to production by using our 3D printing and scanning capabilities allowing us to scan forms into CAD data and print in materials such as ABS and Nylon. Prototyping of parts and tooling solutions further enhances our ability to support our clients when the production button is pushed.

Our Future

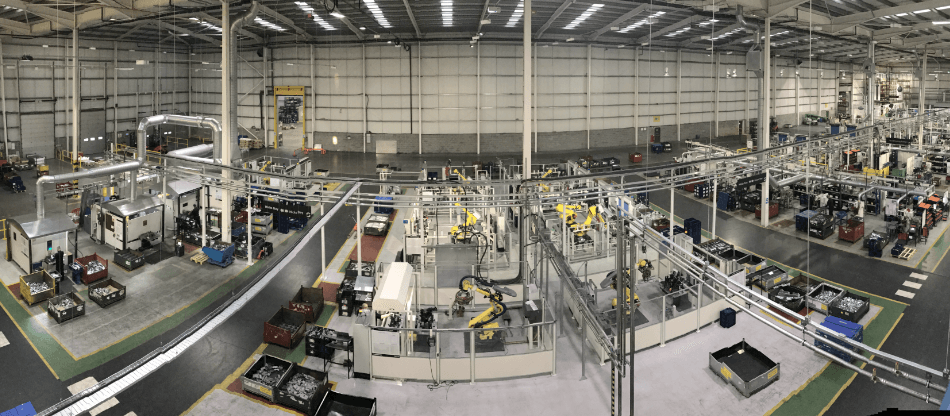

Cyber-Weld has become the chosen partner to a large first tier automotive supplier, we are proud to say we have installed over 60 systems to date, and in some small part enabled the supplier to become a real force in the UK automotive market.

Training and Apprenticeships

Cyber-Weld is a big believer in training the next generation of robotic engineers, we actively encourage all of our employees to further their career path lines.

All our apprentices go through training for a minimum of 4yrs to NVQ level 3. They also have the opportunity to study to ONC and above if capable.